GX Thermostatic Drying Oven

GX Thermostatic Drying Oven

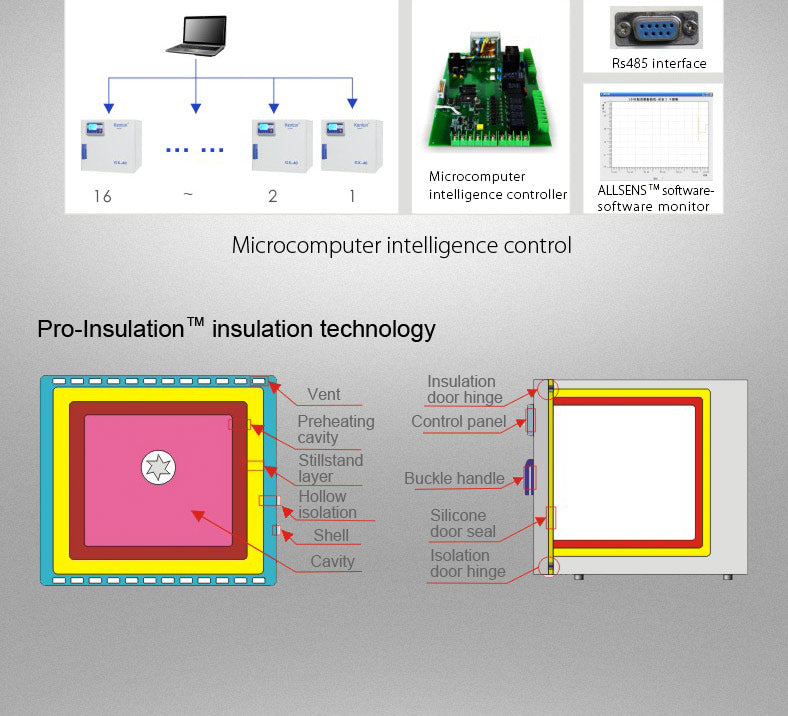

This Kenton manufactured lab drying oven include the technology for preheating cavities Microcomputer control system; forced convection system using air ducts. Insulation technology, temperature homogeneity, and intelligent numerical display.

Basic auxiliary equipment for laboratories and research units, it is widely employed in the fields of drying, sterilization, heated storage, and heat treatment, among others.

Capable of withstanding a range of temperatures, it will offer a steady temperature along with thermal insulation to guarantee the experiment's smooth progression and the sample's cultivation.

Technical Parameters:

|

Product model

|

ALLIGENT-GX Thermostatic Drying Oven

|

||||

|

GX-40

|

GX-70

|

GX-130

|

|||

|

Convection Mode

|

Forced Convection

|

||||

|

Control System

|

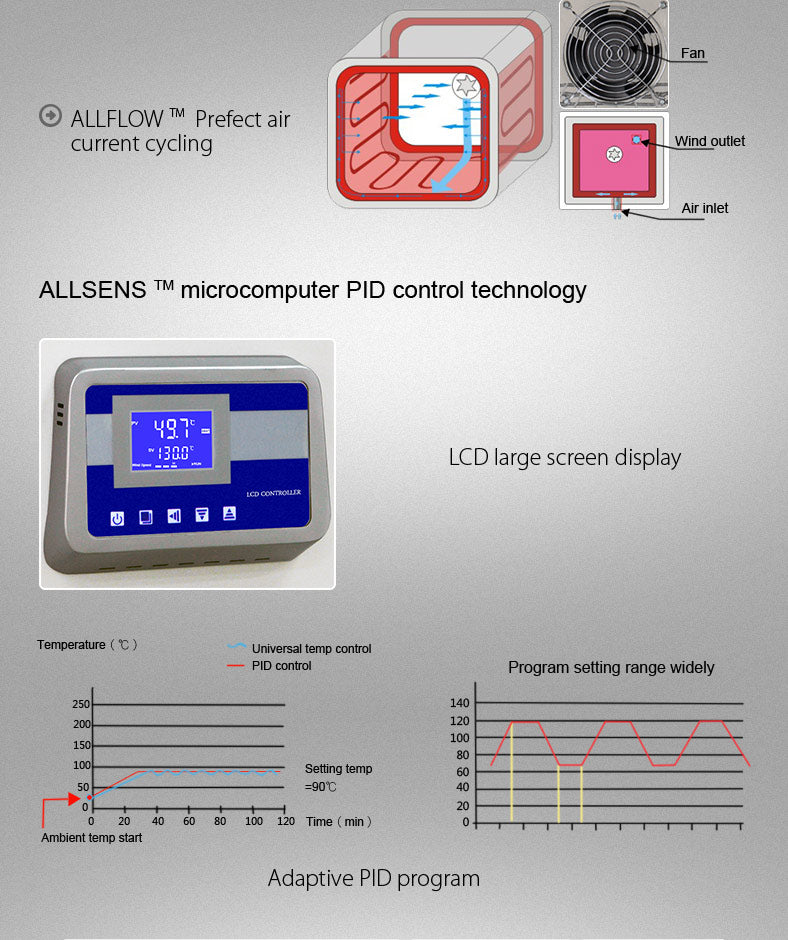

Microprocessor PID

|

||||

|

Temp. Range (℃)

|

RT+5℃~250℃

|

||||

|

Temp. Accuracy(℃)

|

0.1

|

||||

|

Temp. Fluctuation(℃)

|

±0.5(in the of range 50~240℃)

|

||||

|

Temp. Uniformity

|

2%(in the of range 50~240℃)

|

||||

|

Timer Range

|

0~99h,or 0~9999min,can be choose

|

||||

|

Working environment

|

Ambient temperature:10~30℃, Humidity<70%

|

||||

|

Insulation materials

|

Imported environmental protection type material

|

||||

|

External Dimensions(mm) (H×W×T)

|

570×580×593

|

670×680×593

|

770×780×693

|

||

|

Internal Dimensions(mm) (H×W×T)

|

350×350×350

|

450×450×350

|

550×550×450

|

||

|

Interior Volume(L)

|

40

|

70

|

130

|

||

|

Interior steel materials

|

SUS304 stainless steel inner

|

||||

|

The number of standard tray

|

2

|

||||

|

Power(W)

|

770

|

970

|

1270

|

||

|

Supply voltage

|

220V/50Hz

|

||||

|

Net weight(KG)

|

40

|

48

|

65

|

||

|

Shipping weight(KG)

|

43

|

51

|

69

|

||

|

Packing size(mm) (H×W×T)

|

690×660×680

|

790×760×680

|

890×860×780

|

||

More

More

Product introduction:

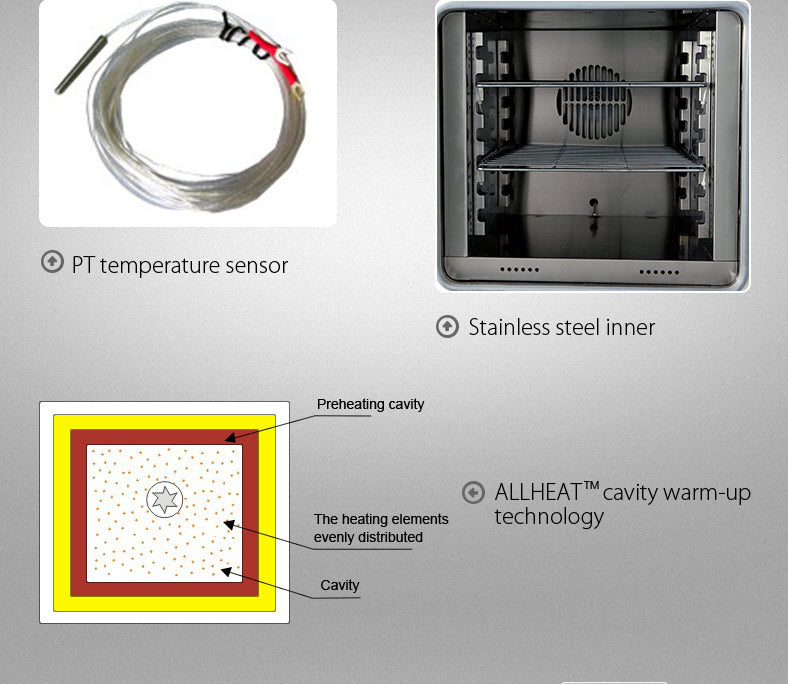

● ALLHEAT™ is an advanced cavity preheating technology that uses heating elements evenly distributed around the inner chamber to pre-heat the cavity inner wall. Then, through heat transfer and forced-fan convection, the cavity temperature of every point can accurately achieve and maintain setting value, ensuring uniform cavity temperature distribution.

● By using ALLHEAT™ series products, customers can reduce costs because of the uniform distribution of heat and low energy consumption, which prevents heat loss.

● ALLFLOW™ - Ideal Air Current Circulation

● ALLFLOW™ air current cycling: ideal for convection, with the shortest temperature recovery period following opening. An optimum outcome of sample cultivation is ensured by a sensible air input and outlet duct design and an internationally renowned finned motor (high durability, low maintenance).

● ALLFLOW™ air current cycling: maintain steady and constant temperature. The fan switch function allows for the adjustment of wind speed, ensuring the ideal atmosphere for sample culture.

Share

Get help with product selection and ordering

Tel: 0086-020-36246586, 0086-020-36246650, 0086-020-36247961

Fax: 0086-020-36246651

Sales Email: kenton@kentonchina.com

Feedback Email: brian@kentonchina.com

Wechat: guan13189191849