KH-120 Industrial Air Blast Drying Oven

KH-120 Industrial Air Blast Drying Oven

The Kenton Industrial Air Blast Drying Oven is manufactured with a double-layered door; digital display and microcomputer-controlled intelligent temperature management; centrifugal wind wheel for even heat distribution; spacious studio area with quick heating times; (may be provided with explosion-proof locks, explosion doors)

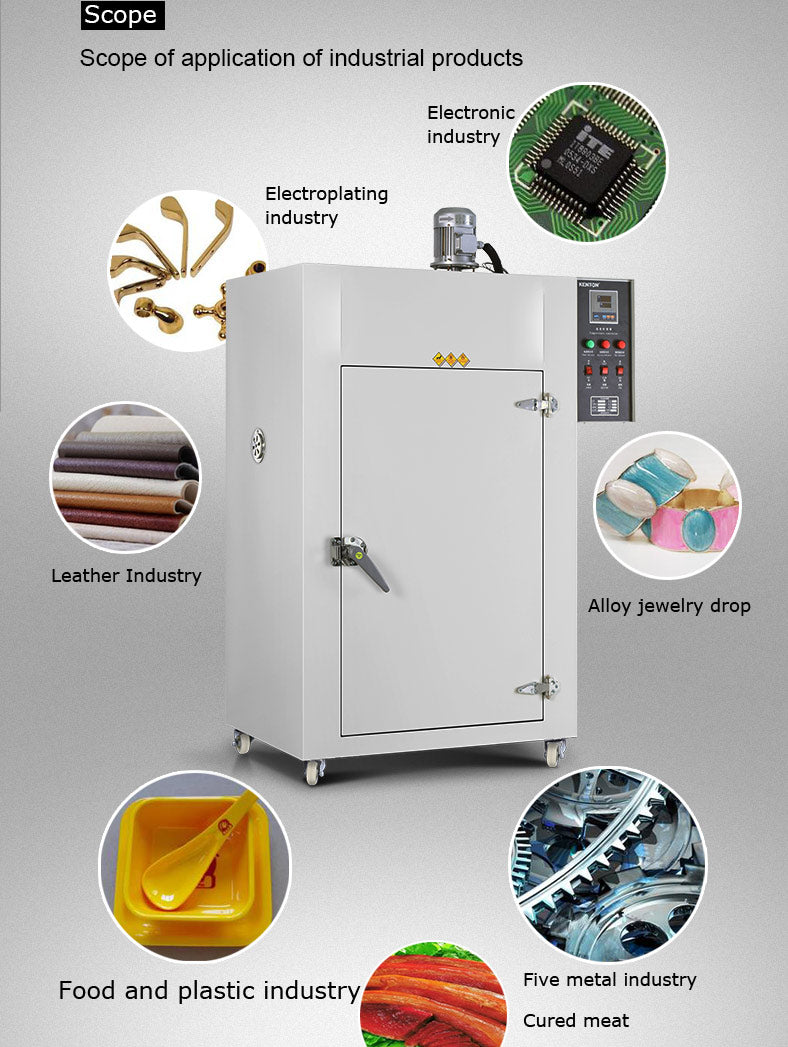

Used for product dehydration and drying, it is appropriate for use in workshops, mining operations, and industries where batch production can run continuously for extended periods of time.

Widely used in the food and plastics business, hardware, electronics, alloy jewelry, electroplating, leather, and electronics industries, among other industries, is not appropriate for processing flammable or explosive materials.

Technical Parameters:

|

Model

|

Voltage

(V) |

Temp

range (℃)

|

Accuracy

(℃) |

Fluctuation (%)

|

Power (KW)

|

Inner size

(mm)

(H*W*D)

|

Overall dimension

(mm)

(H*W*D)

|

Packing size

(mm)

(H*W*D)

|

Net weight

(KG)

|

Shiping weight

(KG) |

|

KH-100C

|

380

|

RT

+5~250

|

±0.5

|

±2

|

4~6

|

1000×600×500

|

1750×1130×700

|

1870×1210×780

|

152

|

156

|

|

KH-100A

|

4~6

|

1000×600×500

|

1750×1130×700

|

1870×1210×780

|

152

|

156

|

||||

|

KH-100AS

|

4~6

|

1000×600×500

|

1750×1130×700

|

1870×1210×780

|

152

|

156

|

||||

|

KH-110C

|

6~8

|

1000×800×600

|

1800×1350×800

|

|

|

|

||||

|

KH-120C

|

8~12

|

1200×900×800

|

2000×1450×1000

|

2120×1530×1080

|

214

|

221

|

||||

|

KH-120A

|

8~12

|

1200×900×800

|

2000×1450×1000

|

2120×1530×1080

|

214

|

221

|

||||

|

KH-120AS

|

8~12

|

1200×900×800

|

2000×1450×1000

|

2120×1530×1080

|

214

|

221

|

More

More

Product introduction:

● The Industrial Drying Oven is mainly used for dewatering, drying, and producing sectors including electroplating, electronics, alloy jewelry drip, food, plastics, leather, hardware, and other applications, but not for the very volatile. Things that can catch fire or explode to prevent an explosion. (If the specifications call for explosion proofing, you have to install safety features like blast doors and explosion-proof locks.)

Features:

● Depending on whether the box is designed with a single door or two doors. Centrifugal wind wheel with a large diameter. uniform heating and cooling.

● The outside is composed of premium cold-rolled steel, sprayed with a shiny finish and a pleasing color scheme. Fit for any type of workshop production.

● Intelligent temperature controller with digital display, microcomputer-based intelligent PID control, and timed functionality.

● Huge wind wheel with a centrifugal diameter. uniform heating and cooling.

● Zinc plating and mirror stainless steel are the two versions' inner chamber materials.

● This series product has a big storage capacity and quick temperature rise.

● KH-100 series for the baking of products in the industries of leather processing, film screen printing, plastic, metal, and so on.

Share

Get help with product selection and ordering

Tel: 0086-020-36246586, 0086-020-36246650, 0086-020-36247961

Fax: 0086-020-36246651

Sales Email: kenton@kentonchina.com

Feedback Email: brian@kentonchina.com

Wechat: guan13189191849