Kenton CST Tri-gas Incubator deliver precise CO2/O2/N2 control for advanced cell culture applications, featuring intelligent touchscreen controls and professional infrared gas sensors. The SUS304 stainless steel cavity with UV sterilization ensures contamination-free environments while automatic gas sequencing maintains optimal conditions. CE certified with 3-year warranty and validation services (IQ/OQ/PQ) available.

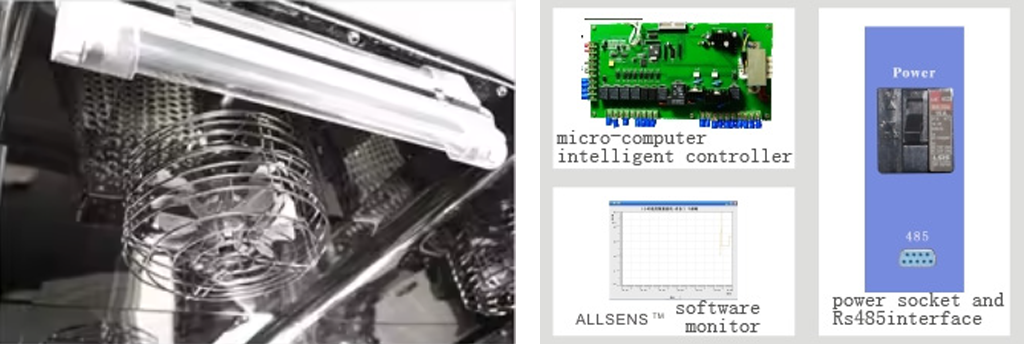

The touchscreen controller integrates professional infrared CO2/O2 sensors to precisely regulate three-gas mixtures (CO2/O2/N2). The system intelligently sequences gas injection - prioritizing O2 when >23% or N2 when <19% - to ensure accurate concentration maintenance before introducing CO2.

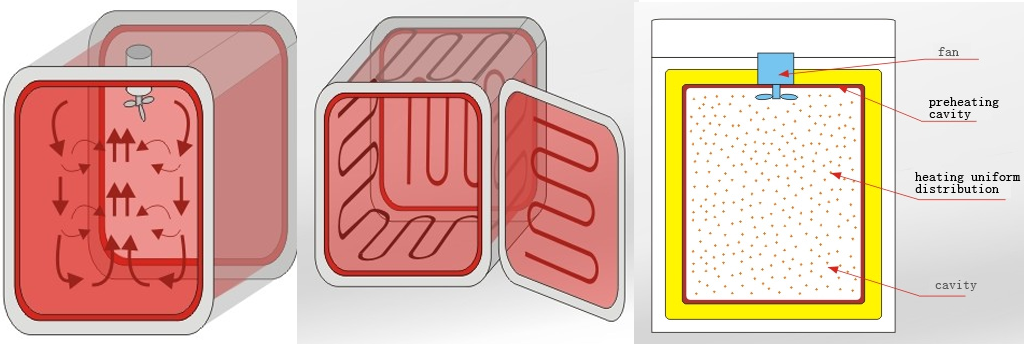

The fan and air intake valve are automatically closed when the door is opened, reduce the pollution caused by the entry of external air. Equipped UV sterilization and filtered air intake to eliminate cross-contamination risks.

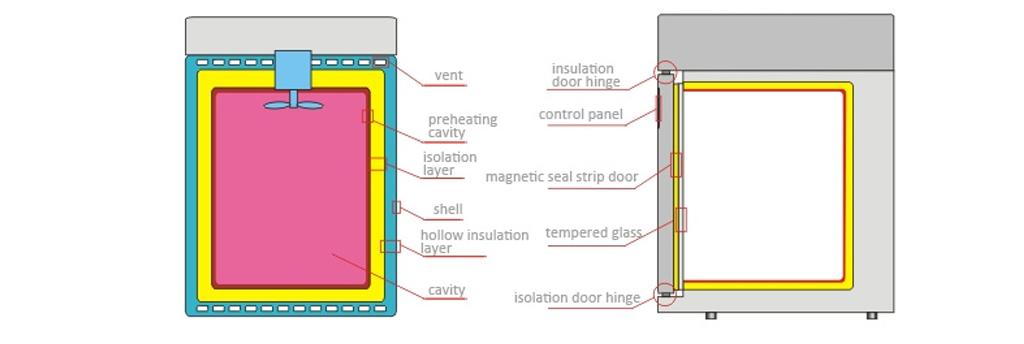

Constant temperature system is equipped in the door to reduce the influence of external environment on the temperature of the inner samples. SUS304 stainless steel inner adopts seamless welding and bonding process to ensure the temperature stability and eliminate interference caused by external factors.

| Model | CR-80 | CR-160 | CST-80 | CST-160 |

| Convection Mode | Forced Convection | Forced Convection | ||

| Control System | PID intelligent touch screen control panel | PID intelligent touch screen control panel | ||

| Temp. Range | RT+5℃~60℃ | RT+5℃~60℃ | ||

| Temp. Accuracy | 0.1 | 0.1 | ||

| Temp. Fluctuation(37℃) | ±0.3 | ±0.3 | ||

| Temp. Uniformity(37℃) | ±0.5 | ±0.5 | ||

| CO2 Range | 0~20% | CO2: 0~20%, O2: 1~25% | ||

| CO2 Sensor/Uniformity | IR sensor(±0.1%) | CO2(±0.1%), O2(±0.1%) | ||

| CO2 Recovery Without overshoot (after 30 seconds door opening to 5%) | ≤2 minutes | ≤2 minutes | ||

| Temp. Recovery Without Overshoot(after 30 seconds door opening to 37℃) | ≤8 minutes | ≤8 minutes | ||

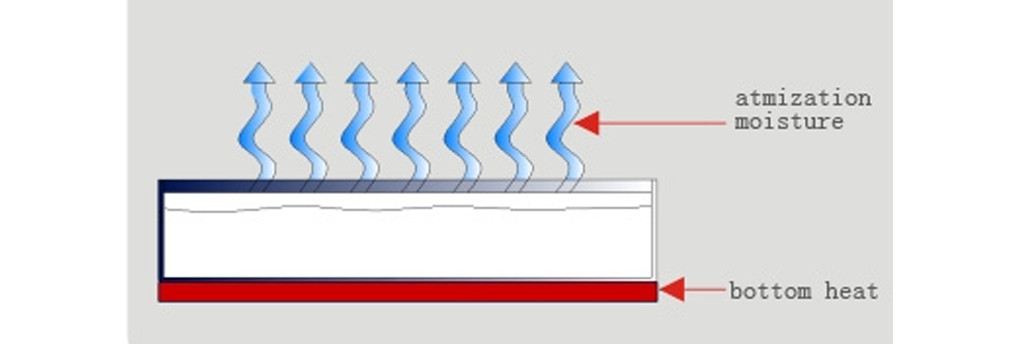

| Humidification Method | Humidity Pan>95%(with Temp. display) | Humidity Pan>95%(with Temp. display) | ||

| Working environment | Ambient temperature:10~30℃, Humidity<70% | Ambient temperature:10~30℃, Humidity<70% | ||

| Insulation materials | environmental sustainable material | environmental sustainable material | ||

| External Dimensions (mm) (H×W×D) | 755×550×547 | 905×610×687 | 755×550×547 | 905×610×687 |

| Cavity Dimensions (mm) (H×W×D | 500×400×400 | 650×460×540 | 500×400×400 | 650×460×540 |

| Cavity Volume(L) | 80 | 160 | 80 | 160 |

| Cavity steel materials | SUS304 stainless steel | SUS304 stainless steel | ||

| Number of Shelves | 2 | 3 | 2 | 3 |

| Power supply | AC220V/110V | AC220V/110V | ||

| Power Consumption (W) | 500 | 650 | 500 | 650 |

| Net Weight(KG) | 35 | 55 | 35 | 55 |

| Shipping Dimensions (mm) (H×W×D) | 880×630×635 | 1030×690×695 | 880×630×635 | 1030×690×695 |