Kenton's drying ovens offer numerous advantages, including ALLHEAT™ warm-up technology for uniform temperature distribution and

energy efficiency. The ALLFLOW™ air current cycling ensures stable, continuous temperature and optimal airflow for sample drying or cultivation.

Integrated with a smart LCD touch screen, the oven features a PID controller for precise temperature control. It also boasts

Pro-Insulation™ technology for reduced energy loss, ergonomic design for comfort, and safety features like over-temperature protection, making

it ideal for research and industrial use

Drying ovens play a vital role in laboratories, manufacturing, food processing, and quality control. They are used to remove moisture, sterilize equipment, cure coatings or adhesives, and test material performance under heat.

When choosing a drying oven, the temperature range is the key factor. For low-temperature applications, such as drying biological samples, Kenton offers the 303 and DNP electric heating incubators, which provide 5°C to 65°C above room temperature. For more demanding processes like industrial drying or chemical treatments, models such as the 101, KH, and GX series deliver stable performance at temperatures up to 300°C.

What sets Kenton apart is its commitment to quality and reliability. Our drying ovens are engineered to maintain uniform, stable temperatures, ensuring accuracy, efficiency, and long-term durability—helping you achieve the best results in every application. Talk to our team to find the drying oven that fits your requirements.

Drying ovens are essential in modern research for their precise temperature control and uniform heat distribution, ensuring reliable results. With features like SUS304 stainless steel interiors, multi-sided preheating, and digital PID controllers, they provide energy efficiency and consistent performance. Models like the KH large offer over-temperature protection, while others feature uniform airflow for better temperature consistency. These ovens are crucial in various lab environments for drying, sterilization, and heat treatment. Their ability to maintain accurate conditions allows researchers to perform experiments with confidence, making them indispensable tools for material preparation, sample testing, and scientific innovation.

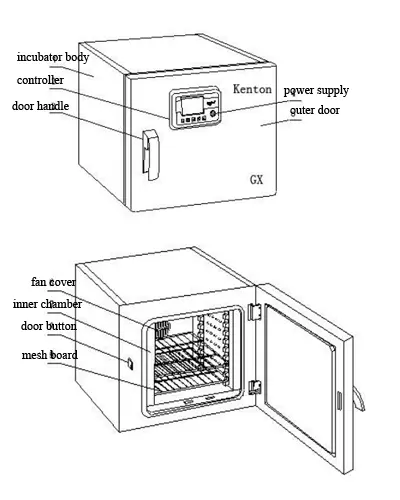

Our comprehensive guide covers setup, usage, cleaning, and troubleshooting. For a detailed product operation manual, please visit our document download page. Follow these instructions to maintain safety and efficiency during drying and maintenance processes.

Our factory has prototype machines available for demonstration, and you can schedule a visit to test them. If you're located further away, we can also send samples to you for testing.

We recommend providing us with your product's temperature requirements before trying it. We can then offer recommendations or tailor a solution based on your specific needs. High temperatures may cause discoloration on the interior of the product, which can affect future sales, so we do not recommend testing if the temperature is too high.

To remove moisture from products and control the humidity of products in the environment.

Single-phase or three-phase power supply, depending on the equipment. It can be used indoors or in workshops, with a recommended room temperature range of 15-30°C.

There are trolleys and trays that can be operated by one person.

Our product specifications are mainly based on the dimensions of the interior (height, width, depth, and volume). Key parameters to report include the temperature range, temperature accuracy, required uniformity, and the material of the interior (all of these can be found in each product's description).